学习任务节点1.学习以下视频材料,复习本章所学的所有宏程序

学习任务节点2.学习以下视频材料,掌握本章作业的分析过程和宏程序调用过程

学习任务节点3.学习以下视频材料,掌握型腔零件结构分析和宏程序调用过程

学习任务节点4.学习以下材料,掌握复习本章所有宏程序

第16次作业演示过程

宏程序:

%

O4004

(开放区域矩形X向行切加工宏程序)

(X 矩形起点X坐标#24)

(Y 矩形起点Y坐标#25)

(Z 矩形起点Z坐标#26)

(U 矩形终点相对于起点X向坐标#21)

(V 矩形终点相对于起点Y向坐标#22)

(W 矩形终点相对于起点W向坐标#23)

(D 刀具直径#7)

(Q每层切削深度#17)

(I行切步距#4)

(F进给速度#9)

#1=#5003

IF[ABS[#21] LT #7] GOTO 1100

IF[ABS[#22] LT #7] GOTO 1100

#33=#21/ABS[#21]

#24=#24+#33*[#7/2]

#21=#33*[ABS[#21]-#7]

#33=#22/ABS[#22]

#25=#25+#33*[#7/2]

#22=#33*[ABS[#22]-#7]

(计算层数及每层切削深度值)

#2=#23/#17

#2=FUP[ABS[#2]-0.01]

#17=#23/#2

(计算行切次数及行切步距)

#3=#22/#4

#3=FUP[ABS[#3]-0.01]

#3=ABS[#3]

#4=#22/#3

(循环加工)

#32=1

WHILE [#32 LE #2] DO 1

G90 G00 X[#24] Y[#25]

Z[#26]

G01 Z[#26+#32*#17] F[#9/5]

#32=#32+1

#31=0

#30=#21

WHILE[#31 LE #3] DO 2

G90 G01 Y[#25+#31*#4] F[#9]

G91 G01 X[#30] F[#9]

#31=#31+1

#30=-#30

END 2

G90 G01 Z[#26] F[#9]

G00 Z[#1]

END 1

N1100 G00 Z[#1]

M99

%

%

O4005

(开放区域矩形Y向行切加工宏程序)

(X 矩形起点X坐标#24)

(Y 矩形起点Y坐标#25)

(Z 矩形起点Z坐标#26)

(U 矩形终点相对于起点X向坐标#21)

(V 矩形终点相对于起点Y向坐标#22)

(W 矩形终点相对于起点Z向坐标#23)

(D 刀具直径#7)

(Q每层切削深度#17)

(I行切步距#4)

(F进给速度#9)

#1=#5003

IF[ABS[#21] LT #7] GOTO 1100

IF[ABS[#22] LT #7] GOTO 1100

#33=#21/ABS[#21]

#24=#24+#33*[#7/2]

#21=#33*[ABS[#21]-#7]

#33=#22/ABS[#22]

#25=#25+#33*[#7/2]

#22=#33*[ABS[#22]-#7]

(计算层数及每层切削深度值)

#2=#23/#17

#2=FUP[ABS[#2]-0.01]

#17=#23/#2

(计算行切次数及行切步距)

#3=#21/#4

#3=FUP[ABS[#3]-0.01]

#3=ABS[#3]

#4=#21/#3

(循环加工)

#32=1

WHILE [#32 LE #2] DO 1

G90 G00 X[#24] Y[#25]

Z[#26]

G01 Z[#26+#32*#17] F[#9/5]

#32=#32+1

#31=0

#30=#22

WHILE[#31 LE #3] DO 2

G90 G01 X[#24+#31*#4] F[#9]

G91 G01 Y[#30] F[#9]

#31=#31+1

#30=-#30

END 2

G90 G01 Z[#26] F[#9]

G00 Z[#1]

END 1

N1100 G00 Z[#1]

M99

%

%

O4006

(封闭区域矩形凹陷铣削加工宏程序)

(X 矩形凹陷中心X坐标#24)

(Y 矩形凹陷中心Y坐标#25)

(Z 矩形凹陷中心顶部Z坐标#26)

(W矩形凹陷中心底部相对顶部的Z坐标#23)

(A X方向长度#1)

(B Y方向长度#2)

(R 矩形圆角的大小#18)

(C粗精加工标志位#3 #3=0,粗精都加工,#3=1只精加工)

(D刀具直径#7)

(E精加工余量#8)

(Q z向步距#17)

(I 平面步距#4)

(F进给速度#9)

(实际加工范围)

#33=#5003

#1=#1-#8*2

#2=#2-#8*2

#18=#18-#8

(判断是否能够安全螺旋进刀)

IF[#1 LT #7*1.5] GOTO 1100

IF[#2 LT #7*1.5] GOTO 1100

(计算分多少层)

#17=ABS[#17]

IF[#17 LE 0] GOTO 1100

#32=ABS[#23/#17]

#32=ABS[FUP[#32-0.01]]

#17=#23/#32

(计算环切次数和环切步距)

IF[#18 LE [#7/2]] THEN #18=#7/2

#31=0

#29=#4

IF[#18 LE #7] GOTO 1110

#31=[#18-#7]/#4

#31=ABS[FUP[#31-0.01]]

#29=[#18-#7]/#31

N1110 IF[#3 GT 0] THEN #31=0

#31=#31+1

WHILE[#32 GT 0]DO1

#32=#32-1

(螺旋下刀)

G00 X[#24] Y[#25-#2/2+3*#7/4]

Z[#26]

G65 P4009 X[#24] Y[#25-#2/2+3*#7/4] Z[#26+#23-#17*#32] R[#26] I[#7*1.5] D[#7] Q[#17/2] F[#9]

(环切循环)

#27=#31

WHILE[#27 GT 0]DO2

#30=[#27-1]*#29+#7/2

#21=[#1-#30*2]/2

#22=[#2-#30*2]/2

#28=#18-#30

G01 X[#24] Y[#25-#22] F[#9]

X[#24+#21],R[#28]

Y[#25+#22],R[#28]

X[#24-#21],R[#28]

Y[#25-#22],R[#28]

X[#24]

#27=#27-1

END2

(行切循环)

IF[#3 GT 0]GOTO1120

(计算行切范围、次数、步距)

#21=#1-#18*2

#22=#2-#18*2

#5=#22/#4

#5=ABS[FUP[#5-0.01]]

#27=#22/#5

G01 X[#24-#21/2] Y[#25-#22/2] F[#9]

WHILE[#5 GE 0]DO3

G91 G01 X[#21] F[#9]

#21=-#21

#5=#5-1

IF[#5 LT 0]GOTO1120

G91 G01 Y[#27] F[#9]

END3

N1120 G90 G01 Z[#26] F[#9]

G00 Z[#33]

END1

N1100 G00 Z[#33]

M99

%

%

O4009

(螺旋进刀宏程序)

(X 孔心X坐标 #24)

(Y 孔心Y坐标 #25)

(Z 孔底心Z坐标 #26)

(R 孔顶心Z坐标 #18)

(I 孔的直径 #4)

(D 刀具直径 #7)

(Q 每次切削深度#17)

(F 进给速度 #9)

#3=[#4-#7]/2

G90G00X[#24+#3]Y[#25]

Z[#18]

#2=[#18-#26]/#17

#2=FUP[ABS[#2-0.01]]

#17=-[#18-#26]/#2

#33=1

WHILE[#33LE#2]DO1

G03I[-#3]J0Z[#18+#17*#33]F[#9]

#33=#33+1

END1

G03I[-#3]J0F[#9]

G91G01X-#3

G90

M99

%

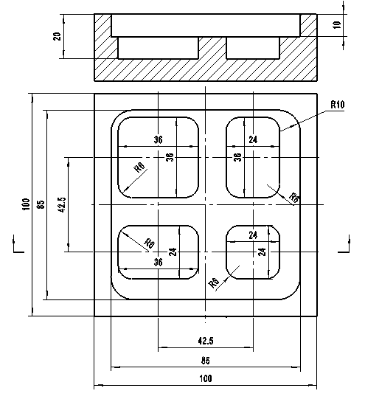

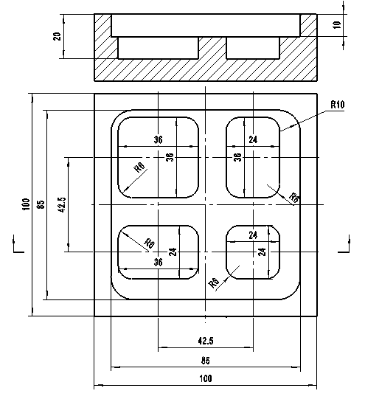

教材练习图档

教材练习的参考

%

O4103

G54 G90 G17 G21

M03S1000

T8 M06

G00 X0 Y0

Z100

Z10

G65 P4006 X0 Y0 Z0 A85 B85 W-10 R10 C0 D12 E0 Q1 I8 F1000

G65 P4006 X-21.25 Y21.25 Z-10 A36 B36 W-10 R8 C0 D12 E0 Q1 I8 F1000

G65 P4006 X21.25 Y21.25 Z-10 A24 B36 W-10 R6 C0 D12 E0 Q1 I8 F1000

G65 P4006 X21.25 Y-21.25 Z-10 A24 B24 W-10 R6 C0 D12 E0 Q1 I8 F1000

G65 P4006 X-21.25 Y-21.25 Z-10 A36 B24 W-10 R8 C0 D12 E0 Q1 I8 F1000

G00 Z100

M05

M30

%